USHINDI - Ultra Low Distortion Transducer Technology

Introducing USHINDI, the Swahili word for victory, the result of PURIFI's extensive research and development effort to eliminate all sources of distortion in a transducer. The results are clear - objectively demonstrated by unparalleled measured data and subjectively, with the purest and most transparent sonic response.

USHINDI technology marks a significant milestone in the world of transducers, as it is the first technology to successfully tackle the challenge of extended-stroke performance. It is now possible for small-cone extended-stroke drivers to outperform large-cone short-stroke drivers, often by a significant margin.

The USHINDI Technology is an array of PURIFI's innovative patented and patent-pending technologies that work together to set new performance standards in the industry. The resulting transducers are ideal for systems that demand the highest level of accuracy, transparency, and overall excellent performance - especially in cases where physical size is a constraint.

USHINDI is available to customers in the form of a line of Transducer Products and as IP's for Licensing.

General vs. OEM-only Products

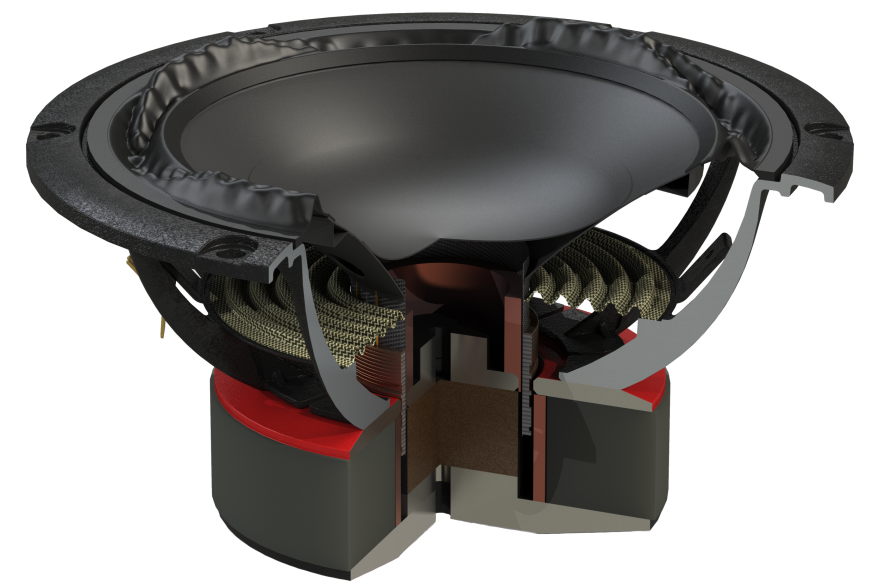

All USHINDI products embody a comprehensive design philosophy, including the patented PURIFI PureDrive ultra-linear motor system, the optimized cone geometry that has undergone mathematical optimization, and the renowned PURIFI NeutralSurround. As a result, all of our products boast unbeatable performance and quality. You don't have to worry about requesting matching pairs, as they all conform to tight tolerances and are inherently consistent.

General Transducer Products

-

Recognized by the PURIFI-red magnet top plate

-

Available with raw paper/fiber or aluminum cone

-

Sold in nice-looking 1-unit boxes

OEM Transducer Products

-

All-black magnet system; more variants

-

Available with PP-coated paper/fiber or aluminum cone

-

Sold only in cost-saving bulk containers

What Makes USHINDI So Unique?

Reducing distortion to such a significant extent requires fundamentally different technology, which ultimately results in very special drivers. Some of the IP's are visible to the naked eye, while others are 'hidden inside' and not so easy to distinguish just by looking at an USHINDI driver.

In highlights, the uniqueness of USHINDI drivers manifests itself in several technical characteristics that should be considered essential data and comparison points for loudspeaker designers. Unfortunately, not all transducer manufactures provide detailed data sheets or relevant technical information beyond the traditional frequency/impedance sweeps and occasional THD vs. frequency plots (the latter often in useless linear scale).

PURIFI advocates for publishing more detailed sets of data (extended data sheets), which will allow loudspeaker designers to make more informed decisions while evaluating and selecting drivers for new loudspeaker design projects. In fact, the sonic performance of a driver can to a large extend be determined by looking at data (a disclaimer here for those who specifically seek drivers with certain distortion/coloration/alteration-of-the-music artifacts - this is outside of our focus area.)

Here's some important characteristics worth noticing:

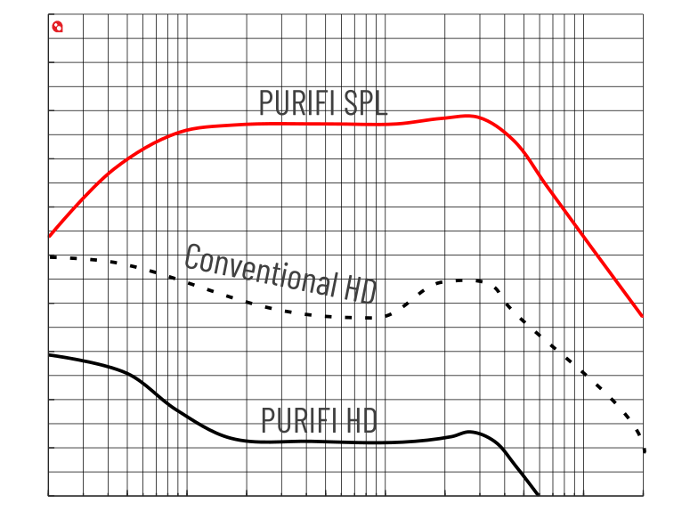

Ultra Low Harmonic Distortion (HD)

If a driver exhibits low HD it may be a suitable candidate for further evaluation. A driver with high HD will cause audible coloration or alteration of the music and is not a suitable component choice if the goal is a pure and transparent audio system.

PURIFI's quest to eliminate sources of nonlinearities and reduce HD to the levels comparable to those of good amplifiers, frequently 60dB or more below the signal level, and magnitudes better than competing high-end transducers.

Look for HD vs. frequency plots in logarithmic (y-axis) scale. Plots in linear scale may appear to have low HD, but this is an optical illusion that makes the curve appear to approach zero.

While HD is an important metric, it is not a 'seal of approval'. Different distortion mechanisms may cancel out and produce seemingly low HD in single-tone frequency sweeps, but performance can completely deteriorate in multi-tone situations.

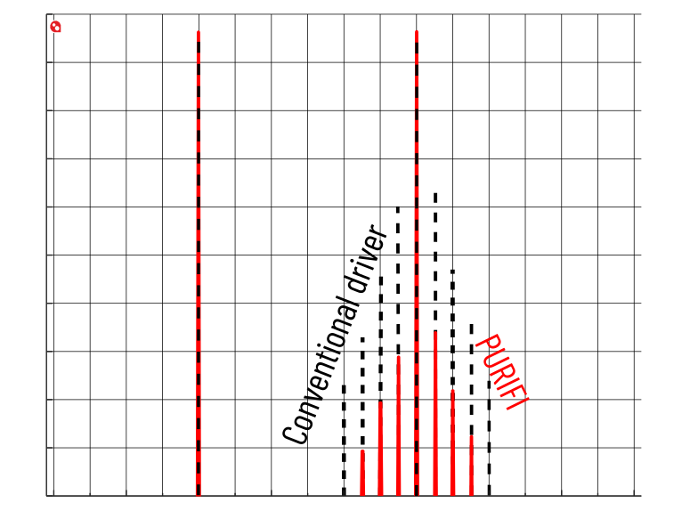

Ultra Low Intermodulation Distortion (IMD)

Intermodulation occurs when, e.g., a mid-frequency tone is modulated by a low-frequency tone. Practically speaking, IMD can cause a bass guitar note or drum kick to warble and distort a more delicate midrange instrument or voice. IMD is a direct contributor to inaccurate sound staging and garbled music reproduction.

The PURIFI PureDrive and PURIFI NeutralSurround reduce IMD, often by a factor of more than 10x compared to competing equivalent-sized high-end drivers.

A simple approach to analyzing IMD is to perform two-tone FFT measurements. IMD will reveal itself as sidebands around the fundamentals. The lower the sidebands, the better. PURIFI's drivers show exceptionally clean FFT's over a wide range of frequencies and amplitudes, indicating ultra-pure sonic response across the spectrum.

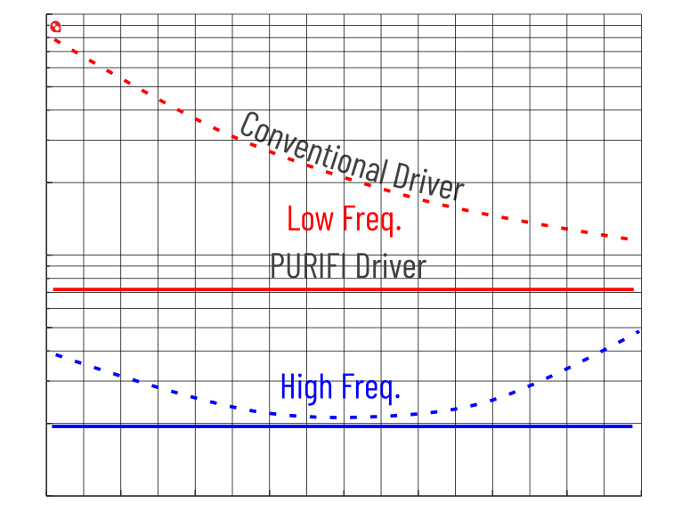

Constant Force Factor vs. Voice Coil Position, Bl(x)

Force Factor (Bl) tends to change with position. A drooping Bl curve will cause mid-frequency signals to be amplitude modulated by low-frequency tones resulting in significant amounts of IMD and a warbling sound or muddy midrange.

The PURIFI PureDrive motor reduces both position- and current dependent Bl a factor of 10 or more compared to existing high-end drives. The result is a crystal-clear midrange, even at high SPLs.

Look for Force Factor vs. Position plots, which should ideally be standard content in any transducer datasheet. PURIFI's drivers show very flat and symmetric curves over a wide excursion range, compared to competitors' often parabolic and asymmetric slopes.

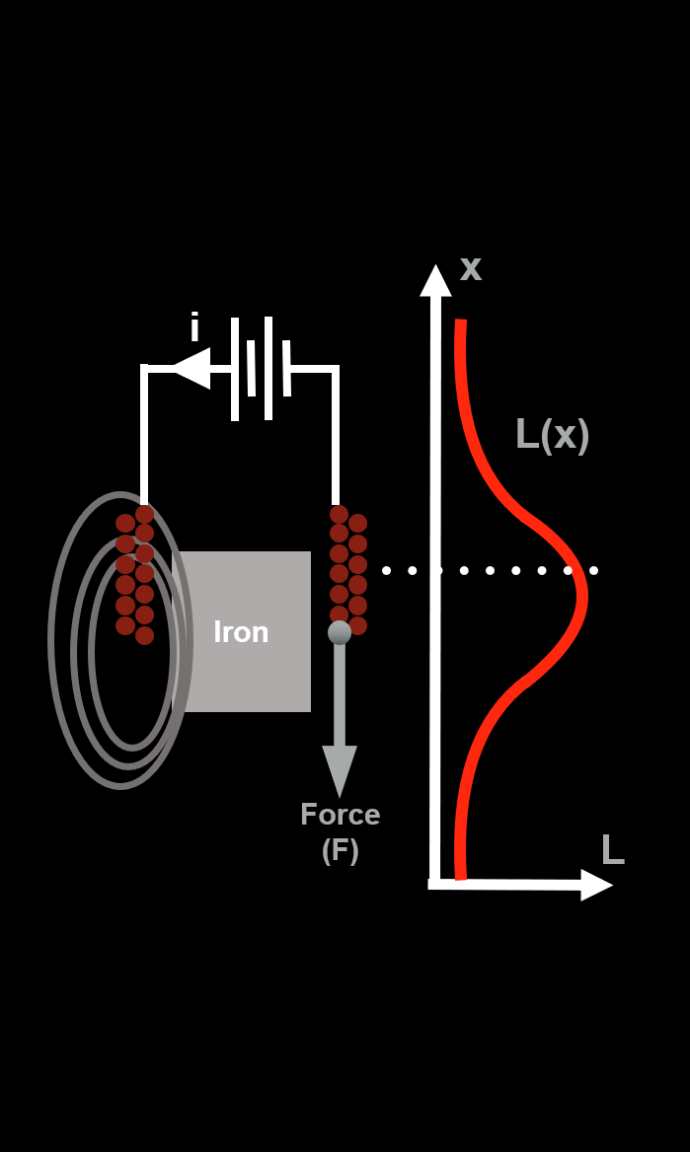

Constant Inductance vs. Voice Coil Position, Lgen(x)

The inductance of the voice coil tends to vary with position, which modulates the current and produces amplitude modulation type IMD.

The PURIFI PureDrive reduces this effect by more that 10x over conventional high-end drivers, resulting in lower IMD and purer audio.

The electrical behavior can be visualized in Inductance vs. Position plots, preferably repeated at multiple frequencies. The ideal behavior is a set of ruler-flat lines, as achieved by PURIFI drivers, whereas most competing products will display sets of heavily slanted or asymmetric curves, indicating large amounts of distortion.

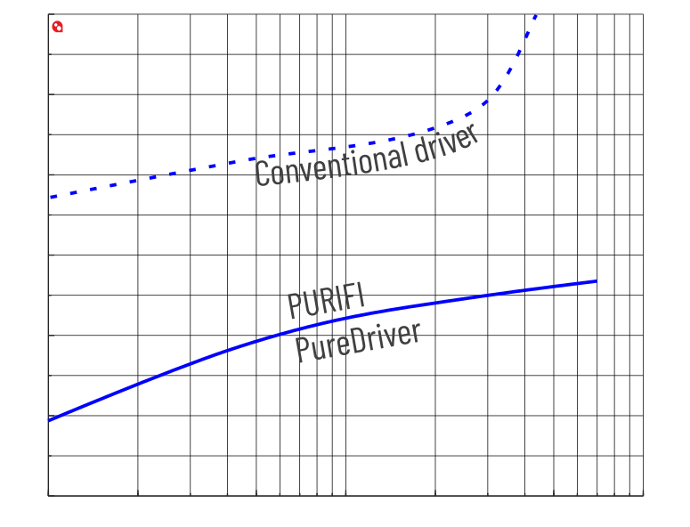

Ultra Low Current Distortion vs. Current Amplitude

On a deeper technical level, the current distortion vs. current amplitude is important because it reveals Magnetic Hysteresis Distortion (MRD), which is an audible artifact caused by the millions of magnetic domains in iron having individual memory in the form of hysteresis. The resulting distortion is both unpleasant and dominant in the upper operating frequency band.

PURIFI’s PureDrive motor design reduces MRD distortion to unprecedented low levels and is easily recognized sonically by the grain-free, deep black background to the music.

When evaluating current distortion, look specifically for extremely low 3rd order harmonics in Current Distortion vs. Current Amplitude plots. Unmanaged MRD will surely manifest itself in the form of high 3rd order harmonics, although other issues may also exhibit this behavior.

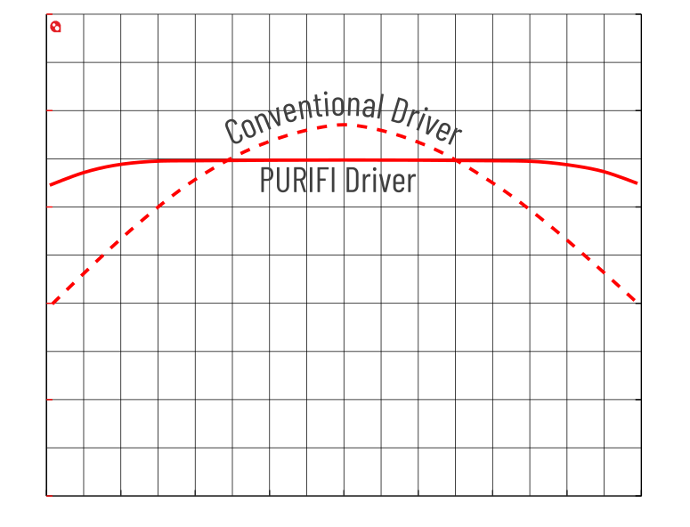

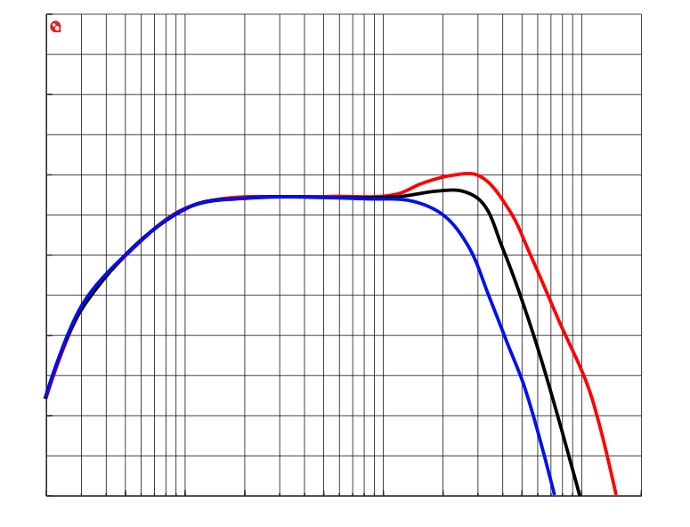

Smooth Frequency Response w/ Excellent Dispersion

Frequency response (FR) and dispersion are common parameters for comparison in audio systems.

PURIFI utilizes a combination of proprietary IPs, including cone geometry optimization, to achieve maximum response flatness. The cone geometry, surround shape (PURIFI NeutralSurround), and the edge stiffening ring (PURIFI ConeRing) are designed to mitigate and manage edge breakups, resulting in a more gradual and soft behavior. Additionally, the high frequency roll-off, where the drivers become directional, is well-controlled and has minimized peaks.

USHINDI paper/fiber drivers use a proprietary pulp mix designed to achieve specific material properties considered optimal for superior sound quality. The aluminum-cone versions are shape-optimized for a high break-up frequency easily integrate into cross-over networks.

Here's some examples:

PTT4.0X04-NLC

- Extended Stroke (X) Driver: +/- 8.5mm (Xlin), +/-13.7mm (Xmax)

- Ultra Low HD: e.g., -62/-66dB (HD2/HD3) @ 1kHz

- Ultra Low IMD: e.g., -48dB @ 50Hz/420Hz

- IEC Power Handling: 200W

Pure

- lower distortion than drivers of much larger size

Powerful - ultimate driver for, e.g., ultra-compact active systems

PTT8.0X04-NAB

- Extended Stroke (X) Driver: +/- 9.3mm (Xlin), +/-15mm (Xmax)

- Wide Bandwidth: super smooth to 5kHz

- Ultra Low HD: e.g., -60/-70dB (HD2/HD3) @ 1kHz

- Ultra Low IMD: e.g., -50dB @ 30Hz/255Hz

Pure - even compared to most dedicated mid-range drivers

Powerful - ultimate driver for, e.g., compact 2-way monitors

Understanding the Origin of Distortion

PURIFI's research showed that the complexity of loudspeaker transducers stems from multiple distortion mechanisms that arise from the interactions between the motor, suspension, and diaphragm. These mechanisms detract from the accuracy and clarity of the music being reproduced, resulting in subpar sound quality. In order to create a precise and accurate transducer, it is crucial to have a deep understanding of these distortion mechanisms and to design the driver to minimize nonlinearities and negative interactions.

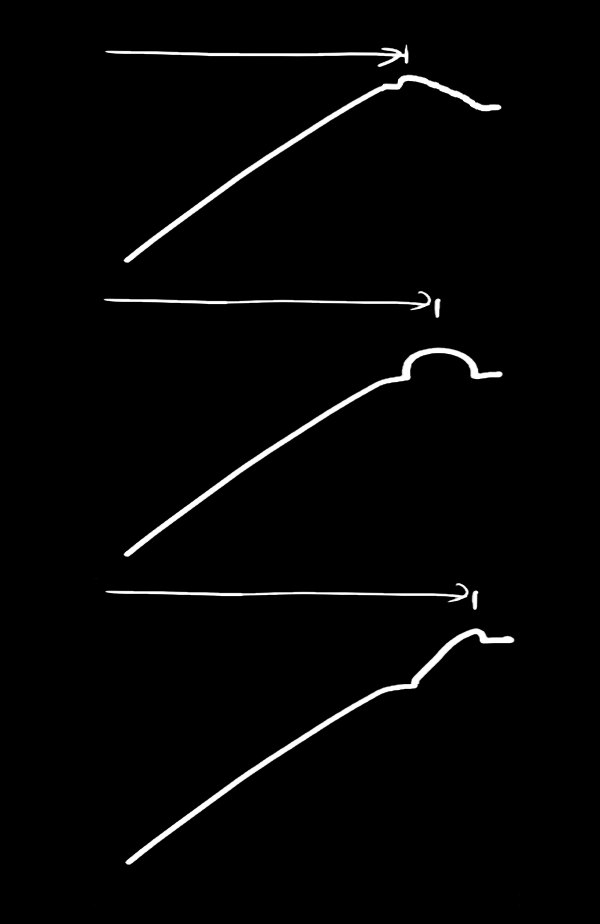

Problem: Surround Radiation Distortion (SRD)

The phenomenon behind SRD is easily conceptualized by pushing on the cone of a conventional "half-roll-surround" driver. When the cone is pushed inwards the effective radiating surface area of cone+surround (Sd) increase, and conversely, when pulled outwards the radiating surface area decrease. This position-dependent effective area deviation can often be as much as 20% of a drivers radiating surface area and is therefor a direct contributor to distortion.

The industry standard method of dealing with Sd modulation is to completely ignore the problem and rely on the generic notion that 'bass distortion is inaudible'. This is certainly not the case. Sd modulation is fundamentally a signal-dependent change in overall sensitivity that is sonically most obvious as amplitude modulation of midrange content. All in all a MUST-fix problem if the goal is excellent sound quality.

Solution: PURIFI NeutralSurround

PURIFI has addressed the SRD issue with its proprietary NeutralSurround technology. This technology uses a special surround geometry that is optimized mathematically, keeping Sd modulation to a minimum, effectively eliminating SRD and significantly reducing IMD effecting the full range of the driver.

Furthermore, the geometry has a number of additional benefits all working collectively to enable unrivalled performance and low distortion from PURIFI's extended-stroke drivers:

1. Practically eliminates Sd(x) Modulation

2. Controls the critical Cone/Surround edge breakup for improved FR, HD and IMD

3. Resilient against Back-Pressure; enables use in very small cabinets

Problem: Force Factor Modulation (FFM)

FFM is a complex beast with negative implications on transducer performance reaching way beyond the established "position dependent force factor", Bl(x), understanding of the root cause of distortion. One of its elements is the modulation that happens when the magnetic field in the voice coils adds itself to the field created by the permanent magnet. Another component which cannot be ignored is the undesirable attraction force caused by voice coil currents and nearby iron parts. This force is quadratic in nature, and to make matters worse, always act in the same direction independent of signal polarity. The position- and frequency dependent inductance of the motor is a telltale and an important metric that should be widespread within the transducer industry as performance indicator. Conventional wisdom, e.g., use of shorting rings, is far from enough to combat FFM.

Solution: PURIFI PureDrive

To address FFM, PURIFI uses a patented combination of topology and numerical geometry optimization to concurrently and independently correct both Bl(x) and FFM. The result is a motor system with exceptional linearity, allowing small cone/long-stroke drivers to outperform much larger transducers.

The larger linear cone displacement lowers harmonic and intermodulation distortion and enables speaker designers to build powerful compact systems with loudness and clarity beyond what has traditionally only been possible with very large drivers.

Problem: Magnetic Hysteresis Distortion (MHD)

Magnetic Hysteresis Distortion is phenomena that happens at any signal level and is therefore not isolated to specific use situations. In different words, it is an ever-present unmasked sound-degrading problem. The sound signature can be described as a grainy or hazy backdrop to the music, an almost popping or crackling sound artifact that surely is not harmonic in nature and simply does not belong.

MHD tends to dominate the midrange.

MHD happens when the varying coil current creates a varying flux which in terms magnetize/de-magnetic the millions of magnetic domains in the iron core of a traditional transducer. The memory effect (~programming) of these individual magnetic domains influence how the motor performances. In other words, past signals affect present and future performance.

Solution: PURIFI PureDrive

PURIFI achieves the benefits of "iron-free" transducer designs in a significantly more manageable and cost efficient manner by combining the PURIFI PermanentCore and a set of numerically optimized full-height in-gap shorting rings that do not negatively affect L(x) as traditionally seen.

The PURIFI PureDrive topology effectively combats both MHD and FFM, as demonstrated by objective measurements of distortion vs. current (as published in all data sheets) and through listening tests that reveal a deep black background and refined detail in the critical mid-frequency range.

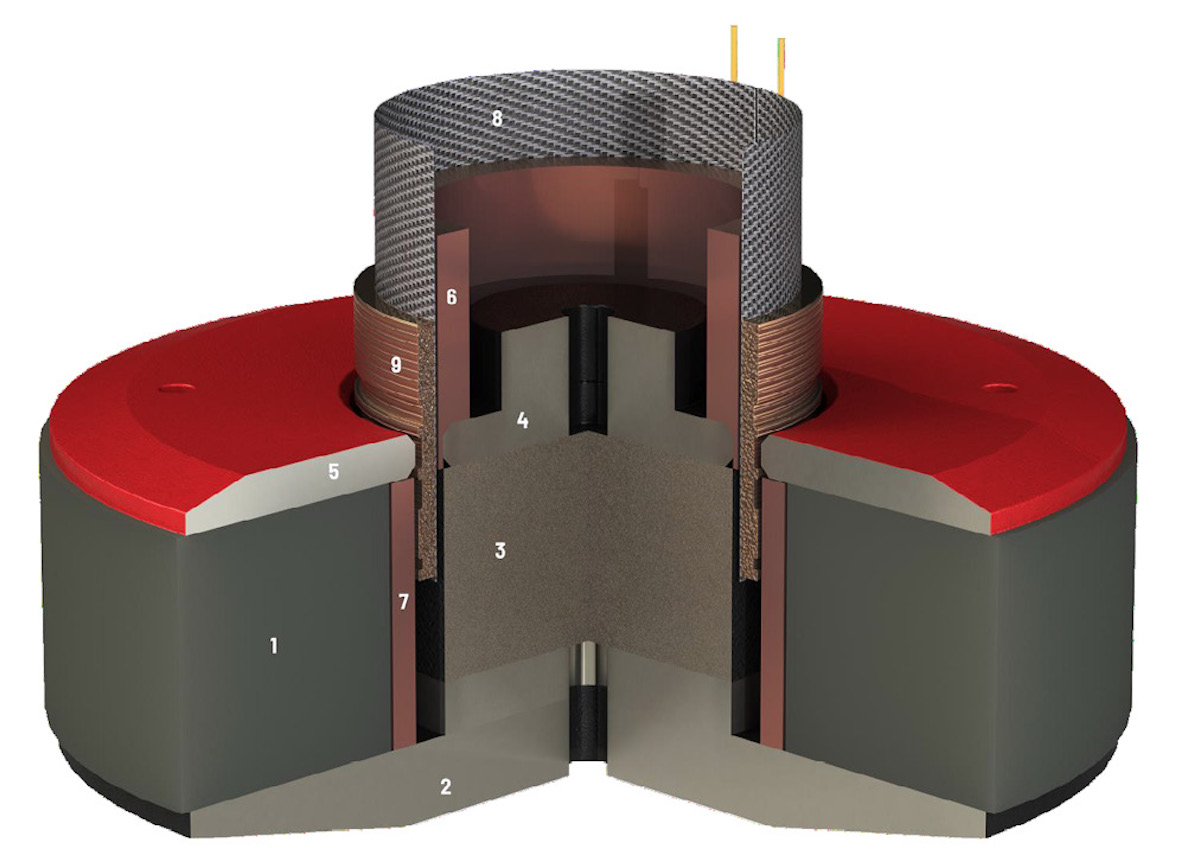

PURIFI PureDrive

The PURIFI PureDrive ultra-linear transducer motor might look ordinary from the outside, but a closer look inside reveals its differences and exceptional qualities. Highly optimized patented parts and geometries co-optimized to battle both Force Factor Modulation (FFM) and Magnetic Hysteresis Distortion (MHD) resulting in peerless levels of linearity.

1. Ferrite magnet

2. Bottom plate; cold-rolled low-carbon steel

3. PURIFI PermanentCore

4. PURIFI TopHat

5. Top palate;

cold-rolled low-carbon steel

6/7. PURIFI In-gap Shorting Rings

8. Non-inductive former

9. PURIFI VariablePitchCoil

USHINDI - IP Toolbox

PURIFI NeutralSurround

Virtually eliminates Sd(x) modulation and controls the critical cone/surround edge breakup. Resilient against back-pressure making drivers immensely suitable for use in compact systems. Enables ultra-low distortion from small-cone/long-stroke drivers.

PURIFI ConeRing

Works in tandem with PURIFI NeutralSurround to control bell modes and achieve target frequency response and dispersion patterns. Enables use of alternative cone materials which can both save cost and enhance sonic qualities. Additionally, it is crucial in reducing overall distortion.

PURIFI Vibroacoustic Optimizer (Tool)

A proprietary tool that is based on mathematical modeling and finite-element analysis (FEA). It serves as a platform for evaluating the trade-offs between different material properties and design geometries to meet desired specifications.

PURIFI PureDrive Optimizer (Tool)

A proprietary tool that is based on mathematical modeling and finite-element analysis (FEA). It optimizes geometries for PURIFI PermanentCore, TopHat, VariablePitchCoil and ShortingRings

to reach targeted specifications.

PURIFI PermanentCore

A practical solution that realizes the advantages of "iron-free" designs by replacing the pole piece with a material that has low AC permeability while still allowing for proper conductance of the DC field lines. This is crucial in avoiding Force Factor Modulation (FFM) and producing a grain-free backdrop for music.

PURIFI TopHat

Strategically placed and optimally shaped iron element to balance the quadratic attraction force caused by coil currents towards the top/bottom plates. Instrumental in maintaining constant inductance vs. coil position.

PURIFI VariablePitchCoil

Unique winding geometry, numerically optimized for achieving ultra-flat Bl(x). Fundamental for eliminating amplitude-modulation-based IMD and avoiding audible burbling. Enables ultra-low distortion from small-cone/long-stroke drivers.

PURIFI In-Gap ShortingRing

Used primarily to control inductance at high frequencies. Thickness and height are optimized to keep inductance independent of position all the way though the audio band. Also help to reduce eddy currents flowing through the TopHat.