Introduction

The tweeter project has been an intensive R&D effort for the last 3 years. Yes, we know, the long waiting time until it is released is painful for all of us. Since we are getting closer, we want to share some details about the design choice we made. This first blog post is about the fundamental choice of the radiator type, i.e. why did we decide for a hard dome as the radiator?

Background

It became clear that the 3rd party tweeters were a major limiting factor in the demo boxes we designed. Finding a tweeter than can match the qualities of the PTT woofers and midranges proved to be hard. We used initially Air Motion Transformer (AMTs) due to their inherent low hysteresis distortion which is a good match to our woofers. However, AMT’s suffer from poor dispersion and their frequency response had high unit to unit variation and suffers from in band resonances. Moreover, the benefit of wide and smooth dispersion even in the top octave became clear after some experiments. Sadly, most tweeters have a strongly narrowing dispersion in the top octave which simply seems to have become an accepted fact of life. It has even become the norm to seek a predicted in room response that tilts downwards which is the consequence of the poor dispersion of today’s tweeters.

Main requirements for the PURIFI Tweeter

- Wide constant smooth directivity even in the top octave.

- Complete freedom to adjust the dispersion with a waveguide.

- Low distortion, especially ultra-low magnetic hysteresis distortion and IMD.

- High linear volume displacement and power handling to enable 2 way speakers. with PTT woofers crossed down to 1.5kHz.

- Absence of in-band resonances, smooth frequency response.

- Easy to manufacture in an automated high precision process to yield low unit to unit variation, potential for low cost in high volumes.

- Not relying on exotic materials to achieve the above

Properties of Different Radiator Types

The first fundamental question is which type of radiator to use. The tweeter (direct) radiator types fall mainly in 3 main categories:

- Flat radiators (ribbons, AMTs etc.)

- Ring radiators including soft domes.

- Domes & cones.

Finite Element Analysis (FEA) simulations can shed light on the properties of the 3 main types. In following we show the directivity pattern and Directivity indices simulated for an infinite flat baffle with circular radiators all with an outer diameter of 33mm. We focus here on the normalized directivity (i.e., response relative to e.g. on axis) since this property cannot be changed by EQ’ing the driver and thus must be secured by design.

The Directivity Index (DI) is often used to characterize the dispersion of a driver. It is defined as the ratio between the on-axis response relative to the sound power response averaged over all directions. A low DI indicates wide dispersion.

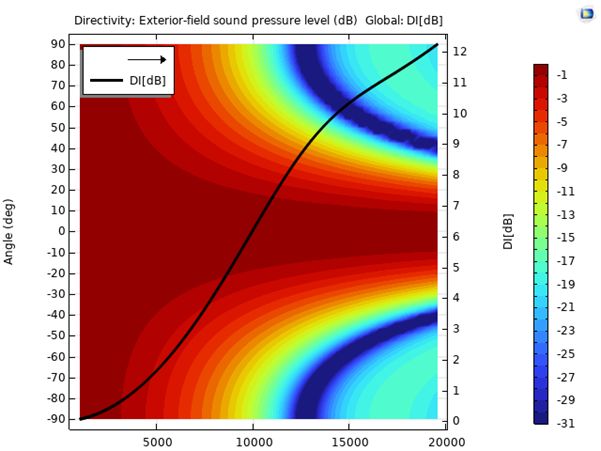

A Round Flat Piston

A flat 33mm disk (i.e., round piston) flush in an infinite baffle.

The

disk vibrates perpendicularly to the baffle plane.

We see that the main lobe around 0 deg narrows strongly but monotonically towards 20kHz and that we have deep nulls off axis (dark blue canyon) in the highest octave. Such nulls indicate that the response is only borderline minimum phase and resembles the effect of cancellations from reflections. Sound arriving from off angles will thus be highly colored compared to sound coming directly on axis. We believe that such a response should be avoided.

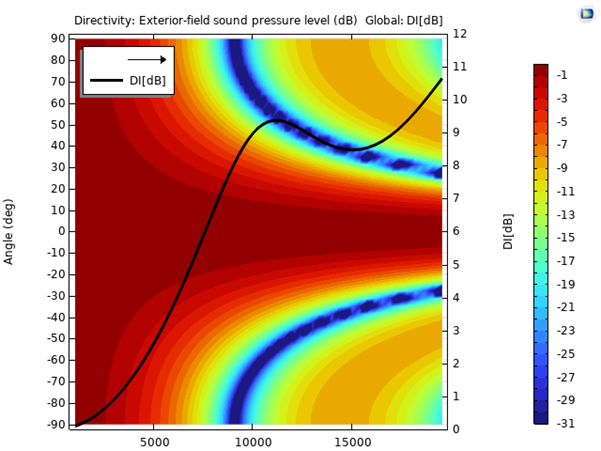

A Ring Radiator

Same as the 33mm disk but the inner 3/4 of the diameter is not vibrating.

The ring radiator shows a faster narrowing main central lobe compared to the full disk. The DI rises faster vs frequency up to around 10kHz. Above 10kHz the DI flattens and becomes lower than for the DI of the full disk. This is seemingly good. However, the off-axis response outside the main lobe is more uneven and comes back up again stronger after the null. This latter effect is the cause of the lower DI since the off-axis lobe increases the averaged power response and since it is in the denominator we get a lower DI. This proves that the DI is not a suitable metric to optimize for since it completely ignores the smoothness of the response.

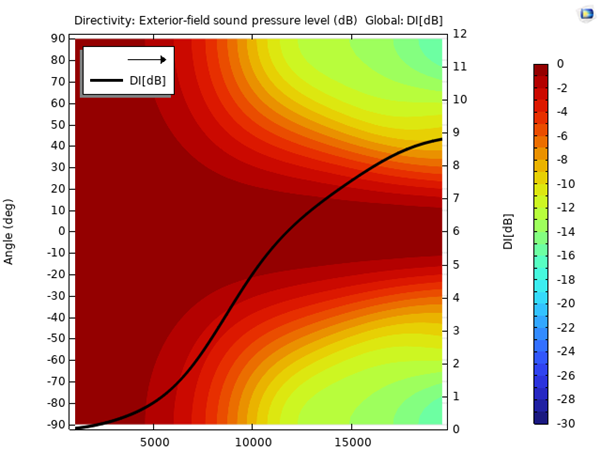

How About A dome?

Finally, we tried a 33mm spherical dome with a radius of 21mm resulting in dome height of 8mm, i.e. a relatively tall dome. Again, moving pistonically perpendicularly to the baffle plane.

Now we see that the main lobe beam is much wider, and the response is smooth and monotonic all the way to 90 degrees without nulls. The DI is smooth and monotonic and is moreover significantly lower than for the flat disk.

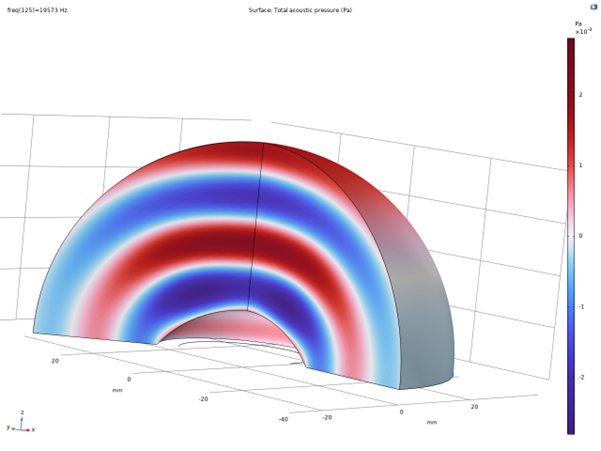

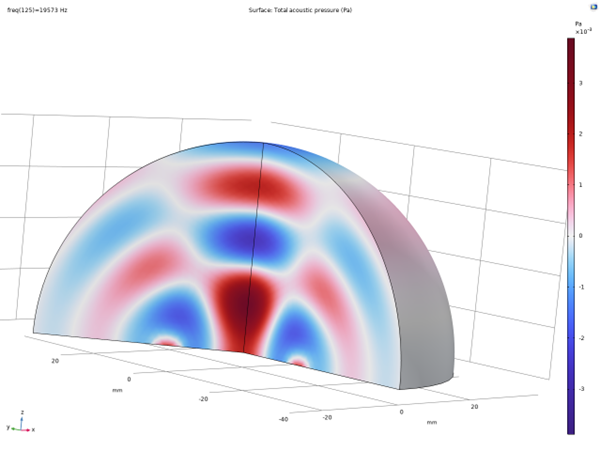

The smooth and wide sound pressure field at 20kHz is illustrated here in 3D:

The Dome

For

comparison, the sound pressure field for the ring radiator reveals the deep

null where the phase flips:

The Ring Radiator

A Dome It Is

The above analysis pretty much settled the question: domes have the best dispersion for the given size. A further advantage of the dome shape is that its inherent geometric stiffness helps achieve a high mechanical break up frequency. A property that has been utilized for most of a millennium to build self-supporting domes, e.g. the Duomo of Florence:

The flat ribbons and folded AMTs typically have in-band resonances which we want to avoid. A soft dome breaks up long before 20kHz (but does so smoothly) and this renders the dome effectively into a ring radiator since only the outer edge effectively radiates above the break up frequency.

Consequently, a tall hard dome is the best choice for the radiator. Aluminum domes are easy to manufacture and has a sufficiently high break up frequency and are quite lightweight. This answered the important question of which radiator type to use.